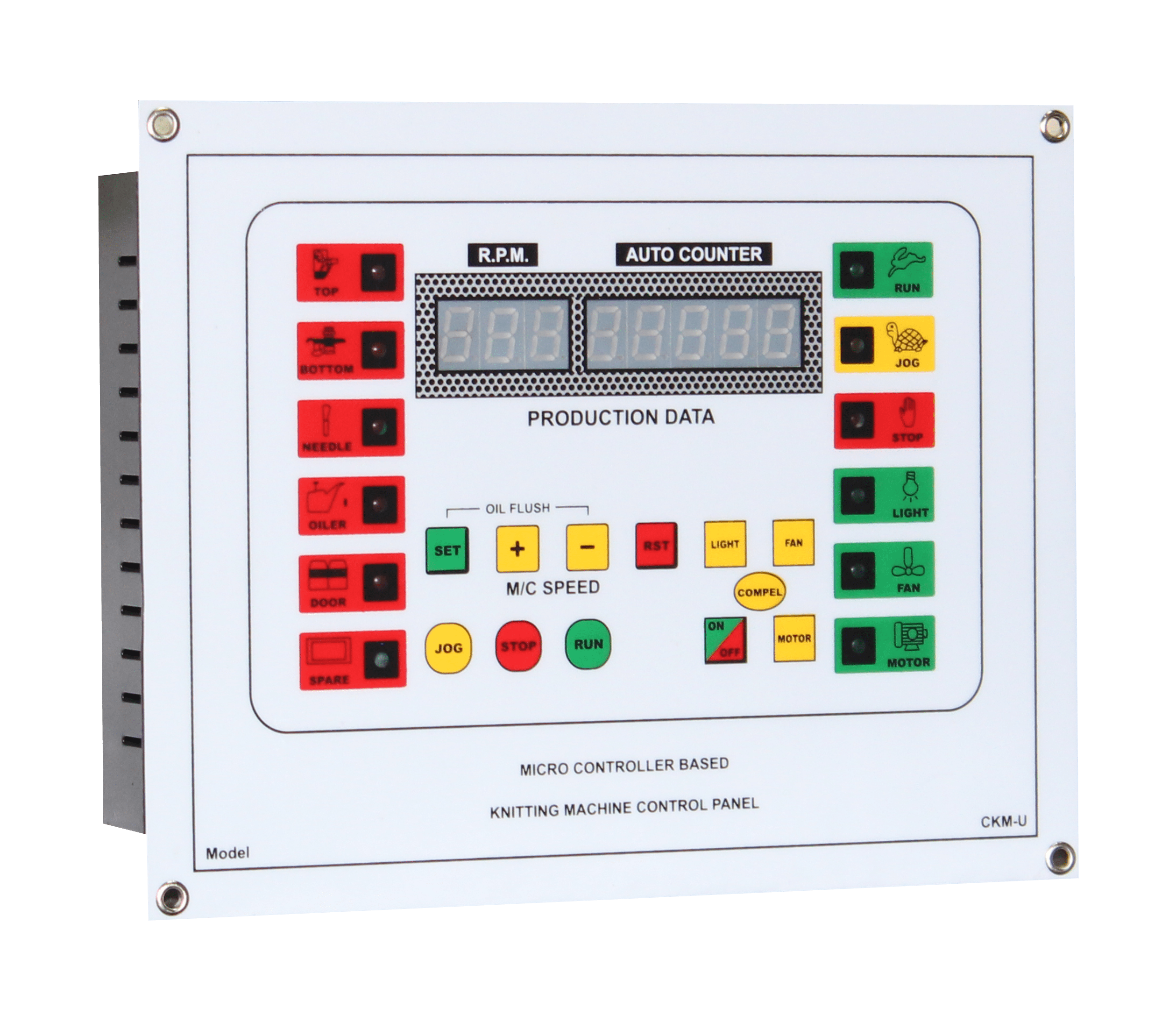

Circular Knitting Machine Controller

Model : CKM-U

Compatible with all the brands and types of Circular Knitting Machines. Standard Size - 270 x 210 mm

- Panel Size : 270 x 210 mm or 10.63 x 8.27 inch

- Panel Cutout Size : 215 x 177 mm or 8.46 x 6.96 inch

- Body Type : Metal body (fabricated using CNC technology and powder coating)

- Fully automatic Micro-Controller based design.

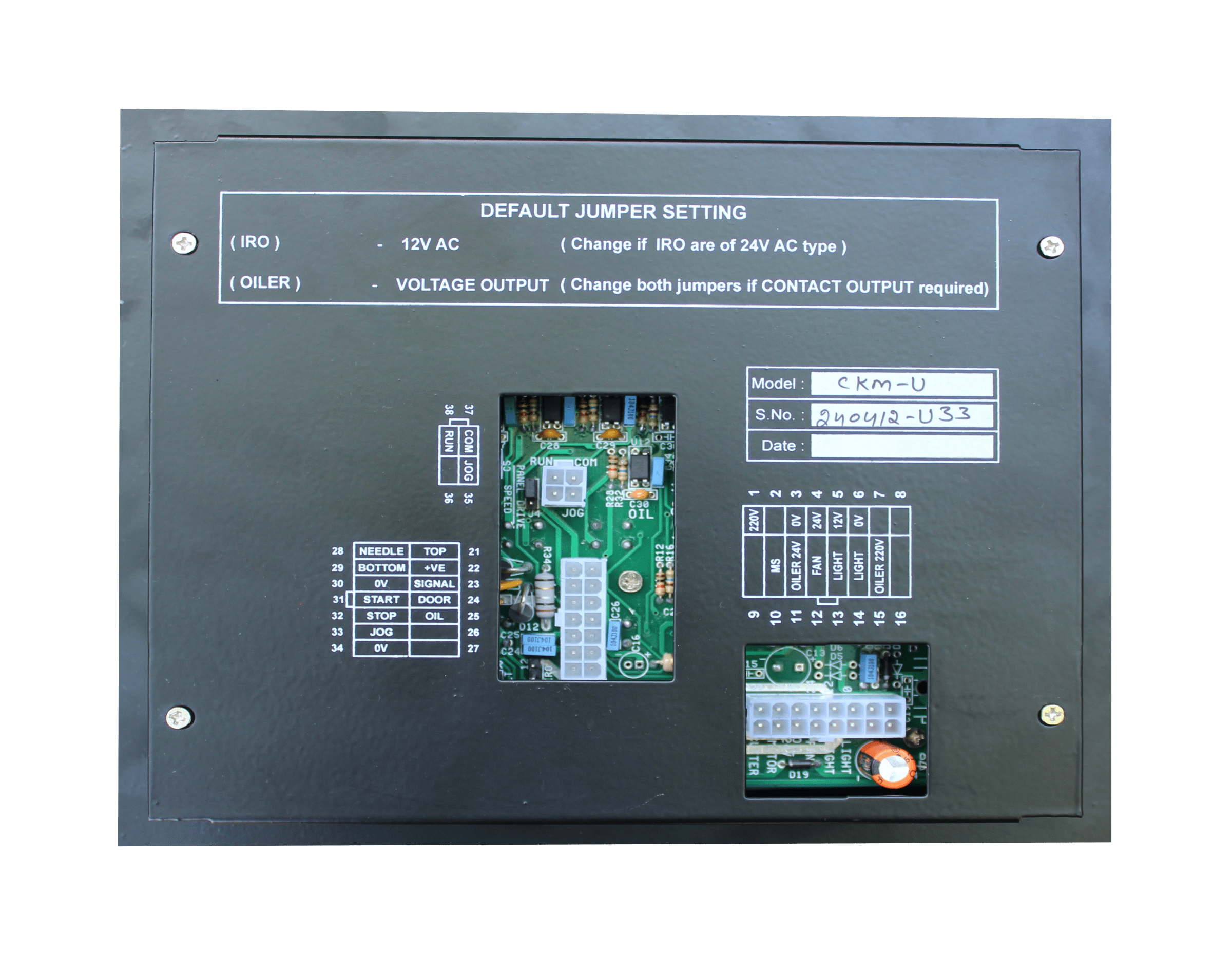

- Operating Voltage : 12V AC

- Counter Range : 0 to 99999

- R.P.M. Range : 0 to 99.9 R.P.M.

- TOTAL Counter Range : 0 to 99999

- FABRIC ROLL Counter Range : 0 to 65000

- Display : Red colour FND display

- STOP Buttons : NO / NC (Selectable)

- Machine Speed Change : Panel Box / AC Drive (Selectable)

- Oiler Coil : Voltage Output / Contact Output (Selectable)

- User Interface : Easy & Simple operation

- Compatibility : White Plugs

Standard Features :

- Allows you to digitally control all the operations of the machine.

- STOPs the machine and shows INDICATION when –

- Yarn breaks (TOP or BOTTOM).

- Needle breakage.

- Door opens.

- Counter value reaching Set value.

- Oil finishes in the oiler.

- Any IRO wire touching the machine body (special IRO short indication on display).

- Manages JOG, STOP, and RUN operations with buttons, indications and display.

- Regulates JOG and RUN speeds separately, with buttons and a speed display allowing for 96 steps of speed adjustment, ensuring precise and stable speed control.

- Records and displays machine revolutions and speed in revolutions per minute.

- Automatically stores operational data with 10-year memory retention.

- Operates the machine only on JOG while the COMPEL or FORCED JOG function is activated (through COMPEL button as well as by pressing the STOP button).

- Counts the TOTAL revolutions separately regardless of fabric roll cutting.

- Manages ON/OFF functions (with buttons and indications) for LIGHTS, FANS, AC DRIVE and COMPEL.

- Controls OILER ON/OFF with indication.

- Operates POWER ON/OFF for the entire panel box with buttons and indications.

Premium Features Offered Only By ACXA :

Displays Cause of Machine Stoppage : Our panel shows the reason for machine stoppage. Access it through settings to quickly identify issues without needing an electrician. Our panel provides you all the details about your machine, making repairs quick and hassle-free. It also highlights mechanical issues for faster maintenance, saving time and boosting production.

RESET Button Lock : The reset button is automatically locked while the machine is running or jogging to prevent accidental counter resets.

Total Fabric Roll Counting : Now you don’t have to count the rolls manually, our panel will count the total number of fabric rolls produced and will display it to help you track production.

Push Button Indication on Display : If the jog, run, or stop push button is pressed, stuck, or becomes direct, it will be displayed on the screen. Unlike other panels that lack this feature, our display immediately alerts the machine operator or electrician to the issue. This saves time and eliminates the need to check every aspect of the machine to identify the problem.

Oiler Option : Our panel offers the option to select either CONTACT output or VOLTAGE output, as various machine brands require one of these for operating the oiler.

Stop Button NO/NC Setting : STOP button type (NO/NC) can be configured via software from the SET button, eliminating the need to alter the machine’s wiring. Simply go to settings and select the button type (NO/NC) your machine uses.

Roll Completion Indication : Roll completion status is displayed on the screen.

Reset Option : When a fabric roll completes, the counter can be reset from the panel’s reset button or by pressing STOP and RUN push buttons together, increasing the lifespan of the reset switch.

Button ON/OFF Memory : If TOP Lamp, FAB Lamp, or FAN button were ON before a power failure, they will automatically be switched ON with a small delay upon power restoration, increasing the lifespan of switches.

COMPEL 1 Option : The COMPEL 1 function can be activated from the COMPEL button or by pressing JOG and STOP push buttons together.

Protection Against Common Problems, Offered Only By ACXA :

AC Drive Protection : When the machine is running at full power, the motor cannot be turned off directly via the motor button to prevent damage to the AC drive caused by sudden voltage drop.

Machine Protection (Mechanically) : The panel gradually decreases the machine speed step-by-step to 1/4 of the total speed in the last 2 rounds before roll completion rather than suddenly turning the machine OFF after roll completion, reducing mechanical stress and extending machine lifespan.

IRO Short Circuit Protection : Protects the panel if TOP, BOTTOM, or NEEDLE wire directly contacts the machine body, preventing the need for frequent panel replacements or repairs.

SENSOR Short Circuit Protection : Safeguards the panel if the sensor’s positive and negative wires are shorted by any cause, preventing unnecessary repairs or replacements.

Accident Prevention Offered Only By Acxa :

You can save a significant amount of your money and time by avoiding major financial losses and downtime caused by common accidents in the knitting industry through our control panels.

When the RUN Push Button gets stuck or becomes direct :

Our panel automatically stops the machine after a 2-second delay if the run push button gets stuck or becomes direct after pressing it. It also provides a continuous indication of the run push button being pressed. This unique feature helps prevent accidents caused by these situations :-

Human Accident Case 1 :

If the run push button gets stuck or becomes direct after the machine operator presses it, there won’t be any indication on other panels to alert them to the issue. Consequently, if the machine stops due to yarn breakage and an IRO activates, the operator may fix the break and proceed to the Winder section of the machine for maintenance or other tasks. However, if the IRO becomes inactive (which commonly happens when the machine gets old) while the operator is in the Winder section, the machine will automatically start running again due to the stuck run push button. This situation could result in severe injury or even death if the machine isn’t stopped immediately.

Human Accident Case 2 :

Many operators skip using the stop button and directly open the gate to the winder section, knowing that the machine will stop automatically. However, if the run push button is stuck, the machine may stop initially when the gate is opened. But if the door closes while the operator is in the winder section, the machine will restart automatically, posing a serious risk of injury or death if not stopped immediately.

Machine Accident Case :

If the run push button gets stuck or becomes direct after the operator presses it, there won’t be any indication on other panels to signal the problem. Consequently, if the machine stops due to yarn breakage and the IRO activates, the operator may fix the issue and proceed to change a needle by dismantling the cam for any reason. However, if the IRO becomes inactive (which commonly happens with older machines) while the cam is still dismantled, the machine will automatically restart due to the stuck run button. This could lead to needle breakage and machine damage, resulting in significant financial loss.

When the JOG Push Button gets stuck or becomes direct :

Our panel quickly shows if the jog button is stuck or becomes direct. Even if the operator doesn’t pay attention to this, our panel will still stop the machine automatically when any IRO becomes active, even if the machine is set to compel(open 2) mode and the jog button is stuck or becomes direct. Other panels don’t do this. If the machine is set to compel(open 2) mode and the jog button is stuck or becomes direct while connected with those panels, the machine will keep running even if there’s a yarn break or an IRO becomes active. This could seriously damage the machine, breaking all the needles or causing the fabric to fall, leading to a big financial loss and wasted time.

Motor Switch Accident Prevention :

Our panel prevents the motor from turning on if the jog or run push buttons get stuck or become direct. So, even if someone tries to activate the motor switch while the machine is undergoing mechanical maintenance and the jog or run button is stuck or becomes direct, the motor won’t start until the buttons are fixed. This prevents human accidents and machine damage since the machine can’t be operated until it’s fully ready to run, with our panel.

Say goodbye to unreliable Chinese panels with no warranty. Upgrade to ACXA and experience :

- 2 years of warranty with cost-free repairs.

- Premium quality and exceptional reliability compared to Chinese panels.

- Unique features to boost your machine’s productivity.

- Exclusive accident protection and prevention functions not offered by any other company.

- Production tracking features to help you keep record.

- Power saving and short- circuit protection features.

- Machine and short-circuit protection features.

- The most affordable price range in the market.

- A durable lifespan with complete repairability.

- A simple and straightforward installation process for user convenience.

- Custom features provided at lower prices based on your requirements and budget.

- Compatibility with all brands and types of circular knitting machines.